-

Automated Universal Testing System with Robotic Specimen Loader

Model: AI-7000-RA1

Standard conformance: Tests can be conducted in accordance with GB, ASTM, DIN, ISO, JIS, and BS.

The AI-7000-RA1 combines universal testing with robotic specimen loading to perform fully automated assessment of mechanical properties, including tensile strength, yield strength, elastic modulus, and elongation. Ideal for material science, production, construction materials, and rubber testing, it offers comprehensive data for scientific and industrial use.

Features:

1. Automation: Automatically pick up and place specimens, minimizing human intervention and ensuring consistent operation.

2. High efficiency: Capture real-time data and perform automatic calculations for reliable analysis using an advanced data acquisition system.

3. Safety: Equipped with overload protection and an emergency stop to ensure secure operation.

-

Hose Outer Cover Abrasion Tester

Model: GT-7012-AI

Standard conformance: ISO/TS 20444-2024.

The GT-7012-AI is specifically designed to determine the abrasion resistance of the outer cover of rubber and plastics hoses.

Features:

1. Equipped with a mandrel that fits snugly within the specimen to prevent specimen distortion under abrasion force.

2. Automatically stops once the specified number of cycles is completed, ensuring precise and reliable testing.

3. Ideal for quality control in rubber and plastics hose industries.

-

Rubber Self-Adhesion Tester

Model: GT-7042-VA

The GT-7042-VA is specifically designed to assess the self-adhesion of rubber.

Features:

1. Utilizes U70 amplifier and Leader II testing software for precise control and measurement.

2. Adjustable test weights allow standard load application of 5N and 25N.

-

Foam Compressive Stress Relaxation Tester

Model: GT-7049-FH

The GT-7049-FH is specifically designed to assess the compressive stress relaxation of foam materials at high temperature.

Features:

1. Notify the user when the specified test time is reached. The equipped cylinder features automatic release.

2. Enlarged viewing window allows easy observation of the specimen during compression.

3. The door interlock ensures testing can only be performed when the door is fully closed.

-

Automatic Rubber Hardness and Density Tester

Model: GT-7190-HD

‧ Density measurement: ISO 2781-2018, ISO 1183-1-2025, GB/T533-2008 Method A, and GB/T1033.1-2008 Method A.

‧ Shore A/D hardness: ASTM D2240, ISO 868, and JIS L6253.

By measuring hardness and density, the GT-7190-AD provides insights into compression and abrasion resistance, as well as the compactness and uniformity of the internal structure of vulcanized rubber, offering valuable data for quality control, material development, and rubber product manufacturing.

Features:

1. Equipped with high-precision transducer and advanced data processing system, supporting various test standards and providing accurate test data.

2. With intuitive operation interface, the system enables one-click testing and easy data export.

3. Supports sequential specimen loading, automatic positioning, and three-points hardness averaging.

4. Automatic water refilling and draining.

-

Elastic Straps Fatigue Tester

Model: GT-7516-A

Standard conformance: GB/T 37635-2019.

The GT-7516-A is specifically designed to assess the fatigue resistance of elastic straps under repeated stretching.

Features:

1. Supports cycle-based stretch, interval-based stretch, and stretch hold modes.

2. Movable grips feature automatic repositioning to simplify workflow.

3. Intuitive touchscreen controller.

-

Plastimeter Aging Oven

Model: GT-FSM01-1

Standard conformance: GB/T 3517-2022 and ISO 2930-1995.

The GT-FSM01-1 is suitable for aging tests of raw rubber.

Features:

1. With HMI and precise temperature control, the plastimeter aging oven allows the temperature to return to 140℃ within two minutes.

2. Applicable to raw and unvulcanized rubber.

-

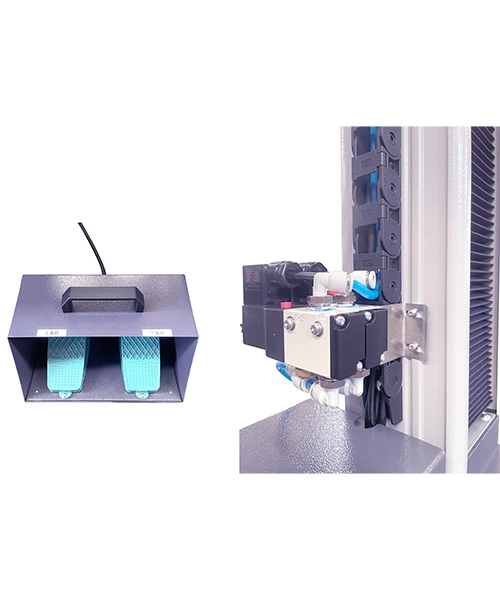

Direct Pneumatic Foot Pedal Switch

Model: FAD-4

The FAD-4 is a non-preload foot pedal switch. It is designed to pair with pneumatic grips, enabling convenient and quick specimen gripping.

Features:

1. Allows gripping control of upper and lower pneumatic grips.

2. Provides direct gripping and supports automatic release under the control of the U70 amplifier and Leader II testing software.

-

Pneumatic Glass Fiber Tensile Grips

Model: AT-P1

Standard conformance: GB/T7690.3-2013.

The AT-P1 grips are specifically designed to test the tensile breaking force of glass fiber yarn.

Features:

‧ Grip type: Pneumatic gripping.

‧ Structure: The arc-shaped pneumatic grips allow quick specimen positioning and secure clamping. Grooved and smooth surfaces prevent specimen damage during testing.

‧ Scope of application: Applicable to various types of glass yarns (e.g., single and cabled yarn).

-

Waterproof Coatings Adhesion Strength Fixture

Model: B-P2

Standard conformance: GB/T16777-2008 7.2 Method B and 8.0.

The B-P2 fixture is designed for testing the adhesion strength of waterproof coatings and their adhesion strength on wet substrates.

Features:

‧ Grip type: Manual gripping.

‧ Structure: The positioning pins at the joint ensure stable clamping without displacement during clamping; the figure-8-shaped design minimizes external force interference in testing.

‧ Scope of application: Used for R&D of construction waterproof coatings and testing the tensile performance of coating materials

-

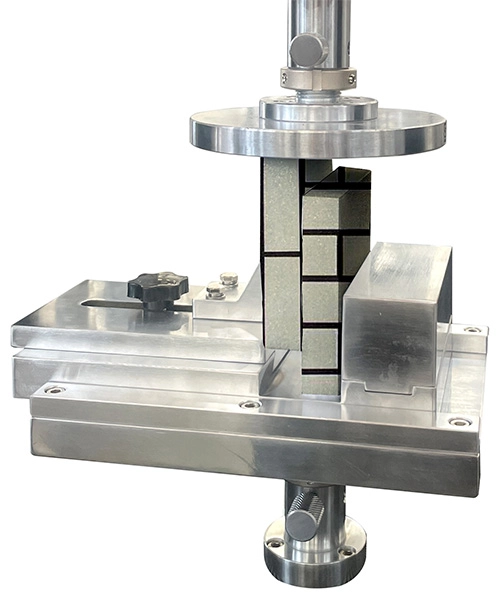

Ceramic Tiles Adhesives Shear Fixture

Model: CS-1

Standard conformance: JC/T547-2017.

The CS-1 fixture is specifically designed for testing the resistance of adhesives used for ceramic tiles to shear.

Features:

‧ Grip type: Manual gripping.

‧ Structure: The lower grip jaws are designed for flexible sliding adjustment, allowing for easy specimen clamping. Pairing with compression platen for testing.

‧ Scope of application: Applicable to ceramic products used for interior and exterior wall tiles, floor tiles, and other related building materials.

-

Garment Trimming Detachment Fixture

Model: RB-7-15

Standard conformance: GB/T 22704 2019-A.3.2.

The RB-7-15 fixture is specifically designed for testing the tensile strength of small garment trimming.

Features:

‧ Grip type: Manual gripping.

‧ Structure: The grooved plate accommodates various components and can be used with optional pneumatic or manual grips.

‧ Scope of application: Applicable to garment trimming, including buttons, pom-poms, and beads.

-

Ball Puncture Fixture

Model: FC-9-13

Standard conformance: DS-267 Method 8.

The FC-9-13 fixture is specifically designed for puncture testing of inflated balls.

Features:

‧ Grip type: Manual gripping.

‧ Structure: Designed with adjustable grips to accommodate soccer balls, basketballs, and rugby balls of various sizes.

‧ Scope of application: Applicable to inflated balls, including basketballs, soccer balls, and rugby balls.

-

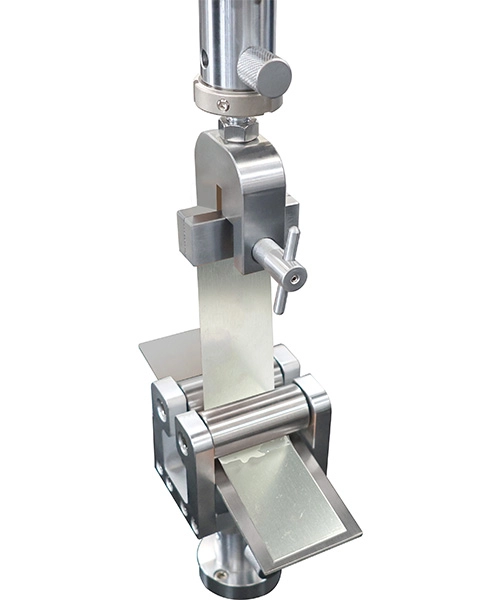

90° Adhesive Peel Grips

Model: FC-9-14

Standard conformance: GJB 446-1988.

The FC-9-14 fixture is specifically designed for 90° peel strength testing of adhesives for bonding metal to metal under ambient temperature.

Features:

‧ Grip type: Manual gripping.

‧ Structure: The lower peel structure features a circular double-roller design that can fit snugly against the test specimen and rotate flexibly to achieve peeling.

‧ Scope of application: Applicable to peel testing of adhesives for bonding metal to metal.